Explore the importance of monitoring and adaptive control in assessing the effectiveness of weather trade model measures in underwater construction initiatives.

– Discuss using remote sensing, underwater sensors, and modeling equipment to music environmental adjustments, screen mission overall performance, and tell adaptive control techniques.

– Highlight the function of stakeholder engagement, interdisciplinary collaboration, and know-how sharing in fostering adaptive potential and resilience inside the face of weather exchange.

Examine the role of policy and governance frameworks in facilitating weather-resilient underwater creation practices.

– Discuss the mixing of weather exchange model concerns into coastal quarter management plans, building codes, and environmental policies.

– Highlight the importance of international cooperation, funding mechanisms, and capability-constructing initiatives in helping weather alternate model efforts in underwater construction.

Adapting underwater production to the demanding situations of weather exchange calls for a multifaceted method that integrates resilient design, sustainable practices, and adaptive control strategies. By embracing innovation, collaboration, and proactive planning, stakeholders can mitigate risks, decorate resilience, and make certain the long-term sustainability of underwater construction initiatives in a converting climate.

As we upward thrust to the challenge of climate alternate, the adaptation of underwater construction practices gives possibilities to shield coastal communities, hold marine ecosystems, and construct a more resilient future for all.

Discuss using recycled materials, low-carbon concrete, and green coatings to minimize greenhouse gas emissions and resource depletion.

– Highlight pleasant practices for minimizing construction-associated pollutants, sedimentation, and habitat disturbance in marine environments.

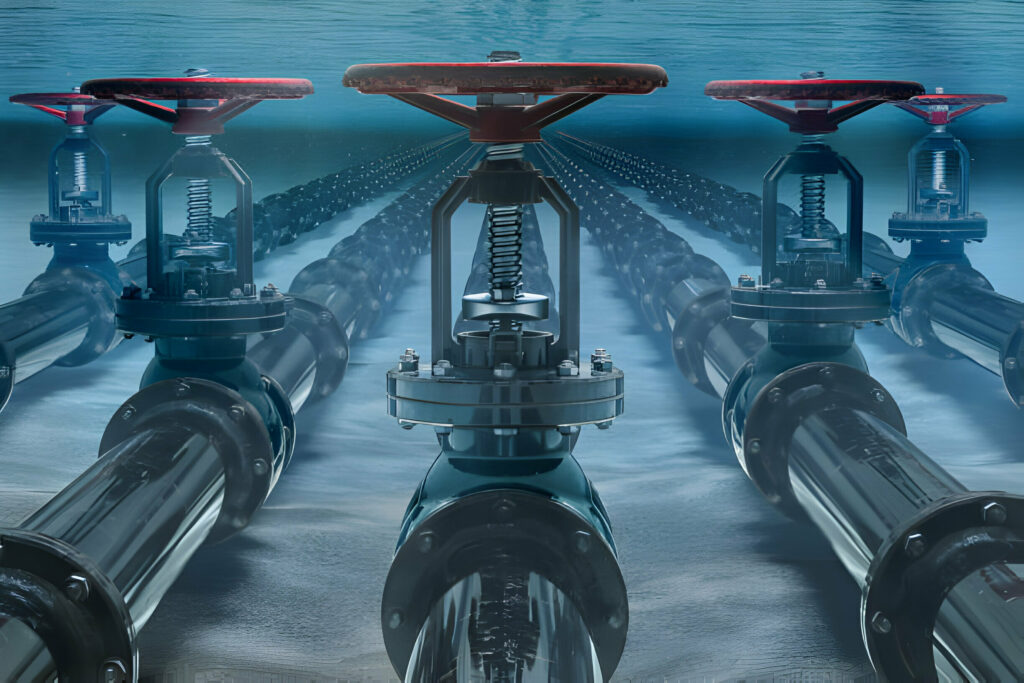

Underwater welding is a crucial thing of underwater production, permitting the restore, maintenance, and production of systems under the waves.

From offshore oil rigs to submerged pipelines, underwater welders play a vital role in making sure the integrity and durability of subaquatic infrastructure.

In this newsletter, we delve into the intricate global of underwater welding, exploring the strategies, demanding situations, and advancements that make it both an art and a technology.

Provide an overview of underwater welding, explaining its significance in underwater creation tasks.

– Discuss the one-of-a-kind kinds of underwater welding strategies, which includes moist welding and dry welding, and their respective blessings and barriers.

– Highlight the specialised gadget and protection tactics required for underwater welding operations, emphasizing the precise demanding situations of running in a submerged surroundings.

Explore the technique of moist welding, wherein the welding electrode is without delay uncovered to water at some point of the welding operation.

– Discuss the device utilized in moist welding, inclusive of guide steel arc welding (MMA) electrodes and specialised welding rigs.

– Examine the strategies employed by underwater welders to hold arc stability, control weld penetration, and make certain right fusion in the presence of water.

Delve into dry welding strategies, which contain creating a sealed environment across the welding location to hold water out.

– Discuss the exceptional strategies to dry welding, which includes hyperbaric welding chambers and habitat structures.

– Highlight the blessings of dry welding, such as stepped forward weld satisfactory, decreased threat of infection, and extended productiveness in comparison to wet welding techniques.